Impresoras 3D

3D Printing Material Solutions

Putting our knowledge and experience to work for your success.

INTAMSYS, a global leader in the additive manufacturing industry, is focused on customer applications by providing innovative additive manufacturing solutions. The INTAMSYS FUNMAT 3D printer series has been on the market for years, providing customers with the perfect combination of industrial 3D printers and high-performance materials. Through years of active insight into customer demand, INTAMSYS accumulated a wealth of knowledge in materials and the printing process. By developing industrial filament solutions that closely resemble commonly used production materials, the INTAM™ series of high-performance filaments was launched. INTAM™ filament and the FUNMAT 3D printer series with optimized slicing software brings customers an unparalleled printing experience. INTAMSYS is committed to providing continued custom material development and third-party material evaluation and certification.

Perfectly matched with INTAMSYS printing equipment

Plug and play operation utilizing pre-set parameters and excellent printing experience out of the box Trouble free and efficient, easy to print Excellent printed results with spectacular details Cost savings of up to 80%

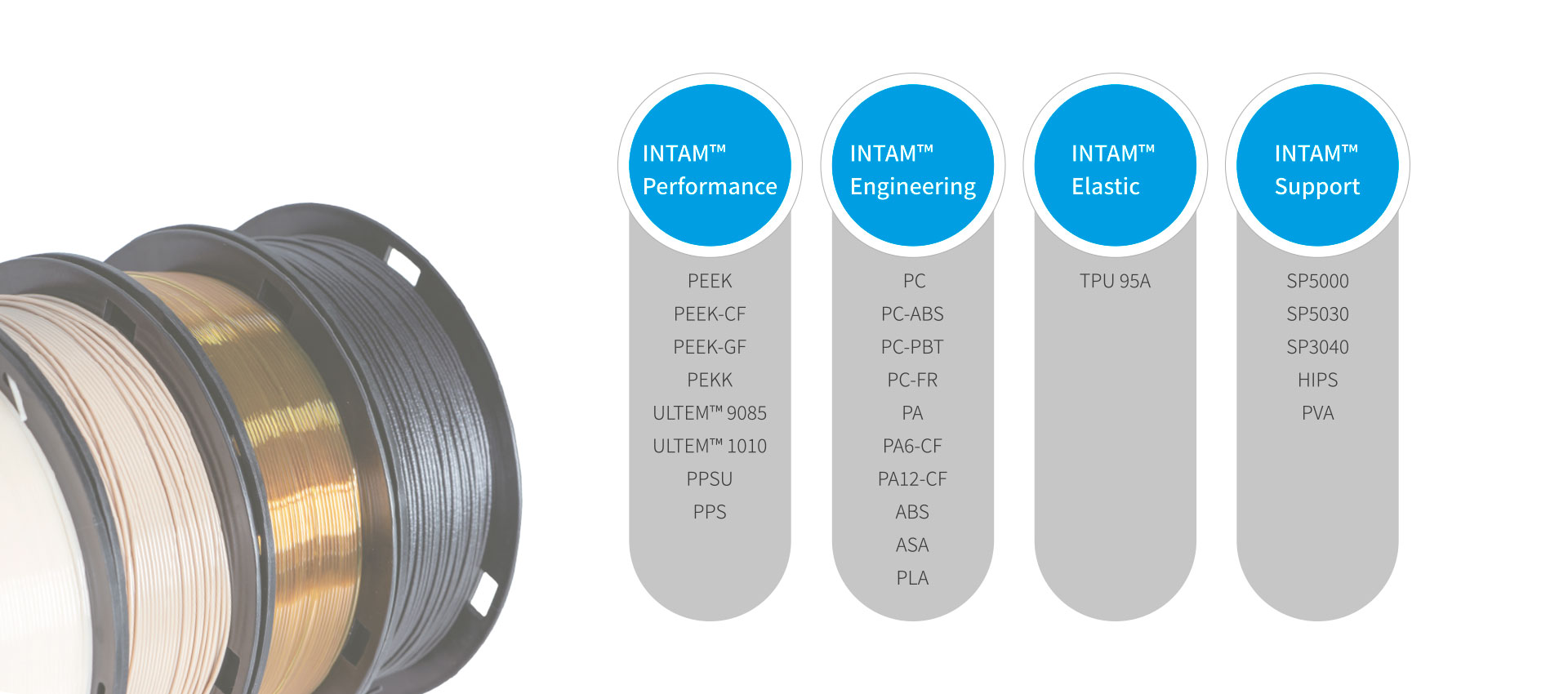

INTAM™ Performance

Selective, economical and practical engineering materials

| PEEK | Semi-crystalline polymer, high strength, good chemical resistance, long-term use temperature of 260℃

Widely used in aerospace, automotive, oil and gas energy, medical, dental and scientific research industries |

| PEEK-CF | Carbon fiber reinforced PEEK, high dimensional stability and weight-to-strength ratio Higher stiffness at high temperatures,HDT A 315°C allows short term usage at even higher temperatures Commonly used for metal replacement, can be used in extreme environments such as aerospace, oil and gas industries |

| PEEK-GF | Glass fiber reinforced PEEK, high dimensional stability and electrical insulation

HDT A 315°C allows short term usage at even higher temperatures Commonly used for metal replacement, can be used in extreme environments such as aerospace, oil and gas industries |

| PEKK | High strength, good wear and chemical resistance, high dimensional stability

Able to withstand hot and humid environments |

| ULTEM™ 9885 | Complies with FST protection standards

Ideal for aerospace and military applications, this includes aviation and railway as well |

| ULTEM™ 1010 | High temperature resistance, high strength and rigidity, strong flame retardancy

Suitable for aerospace, automotive, medical and other industries |

| PPSU | Excellent high temperature and corrosion resistance, electrical insulation

Excellent hydrolysis resistance Widely used in electronic and electrical equipment manufacturing as well as tooling for the medical industrye |

| PPS | High temperature and corrosion resistance, good flame retardancy and mechanical properties

Used in electronics, automobiles, machinery and other fields |

INTAM™ Engineering

Selective, economical and practical engineering materials

| PC | High strength, excellent durability, and printability

Used for product models, brackets, mechanical parts, etc. |

| PC-ABS | Good toughness, high temperature resistance and smooth surface finish Suitable for automotive interiors, lighting equipment, high heat-resistant parts, etc. |

| PC-PBT | PC/PBT polymer blend, high corrosion resistance, maintains high toughness at low temperatures

Used in auto parts, electronic equipment, etc. |

| PC-FR | Highly flame-retardant PC material, achieves V0 performance in the UL flame-retardant test, high heat resistance and high mechanical strength

Used in aerospace, automotive, electronics and other industries with high flame retardant requirements |

| ABS | Durable, high temperature resistance, good toughness

Suitable for automobiles, household appliances, etc. |

| ASA | Complies with FST protection standards

Ideal for aerospace and military applications, this includes aviation and railway as well |

| PA | High mechanical strength and toughness, high temperature, ductility and fatigue resistance

Suitable for industrial parts used in harsh environments |

| PA6-CF | Good strength, high rigidity, and matte surface finish

Used as electronic equipment, fixtures, auto parts, etc. |

| PA12-CF | High strength and rigidity, low water absorption, good interlayer adhesion and high dimensional stability

Used in automotive, aviation, gears and other products |

| PLA | Bio-based polymer material, environmentally friendly and degradable, easy to print, economical and practical

Suitable for a variety of prototypes |

INTAM™ Elastic

Flexible and comfortable material

| TPU 95A | High wear resistance and durability

High flexibility providing comfort and protection Suitable for shoe materials, medical treatment, fashion design and other fields |

INTAM™ Support

Support materials to help complex structure printing

| SP5000 | The preferred breakaway support material for polyaryletherketone (PAEK) high-performance materials

Easily removed with the aid of solvents |

| SP5030 | Breakaway support material, used at high temperatures. Suitable for ULTEM™ 9085 |

| SP3040 | Water-soluble support material. Suitable for ABS, ASA, PA, PA6-CF, PLA, TPU 95A and other materials

Faster dissolution rate |

| HIPS | Breakaway support material, suitable for ABS, PC, PC-ABS, PC-PBT, PC-FR, ASA and other materials |

| PVA | Water-soluble support material, suitable for PA, PA6-CF, PLA, TPU 95A and other materials |